Sydney Success Story: Tai Dragon’s Automated Packaging Solution for Soft Noodles and Dumplings

The Challenge: Packaging "Difficult" Fresh Noodles

An Australian noodle manufacturer was searching for a robust solution to automate their production. Through an online search for "Taiwanese packaging machine manufacturers with export experience," they found Tai Dragon’s case studies and initiated a technical consultation.

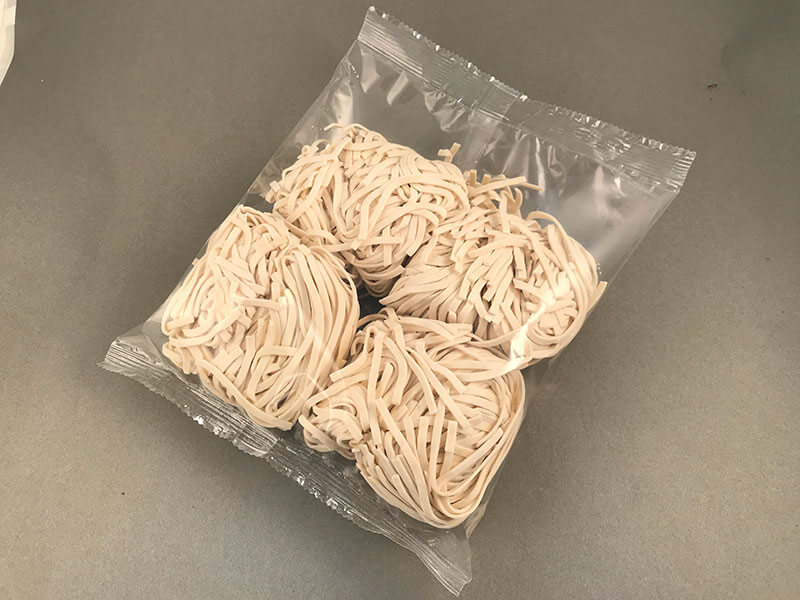

The core challenge was the product itself: Fresh Noodles.

Unlike rigid biscuits, fresh noodles and dumplings are:

- Irregular in shape.

- Soft and easily deformed.

- Highly sticky (flour-based).

Standard flow wrappers often crush soft noodles or cause jams due to sticking. They needed a partner who could understand these nuances—they needed Tai Dragon.

The Solution: Tai Dragon’s Highly Customized Automated Line

After a detailed technical evaluation of the noodle properties, Tai Dragon’s engineering team designed a fully automated packaging line that prioritizes "Gentle Handling."

Key Engineering Customizations by Tai Dragon:

-

Smart Belt-Type Feeding System:

Instead of traditional metal pushers which can mark or squash the dough, Tai Dragon implemented a synchronized belt feeding system. This transports the soft noodles gently into the film tube without compression, maintaining their original shape and texture. -

Intelligent Spacing Detection:

The system automatically detects the product's position and adjusts the feeding distance, ensuring every pack is uniform.

Enhancing Efficiency and Safety

This automated solution allowed the client to expand their factory output while significantly reducing labor costs associated with manual feeding.

Technical Advantages for Difficult Products

-

Anti-Cut Protection System:

Tai Dragon’s cutting jaw is equipped with a smart sensor. If it encounters an obstruction (e.g., a misaligned noodle pack), the cutter automatically retracts. This prevents the blade from cutting through the product, saving both the noodles from waste and the cutter blade from damage. -

Integrated Traceability:

A built-in thermal printing system was integrated to print manufacturing and expiration dates directly on the film, ensuring compliance with Australian food safety standards. This attention to detail is why Tai Dragon Machinery is trusted by food manufacturers worldwide.

Looking for a Specialized Solution for Fresh Pasta?

Handling soft, sticky, or irregular dough requires more than a standard machine, it demands expert engineering. If you are looking to upgrade your production line with a high-performance noodle packaging machine that prioritizes product integrity and efficiency, trust Tai Dragon to deliver the result. Contact our team today to discuss your specific customization needs.